Some Known Questions About Uv Filtration.

Table of Contents7 Simple Techniques For Uv FiltrationHow Uv Filtration can Save You Time, Stress, and Money.The Definitive Guide to Uv FiltrationHow Uv Filtration can Save You Time, Stress, and Money.

Elimination of preference and odor substances from the water.: Softens the water.: Purification to remove small particles as well as sanitation to eliminate infections and also microorganisms, and guarantee an inappropriate setting for virus and also germs growth throughout the circulation system.

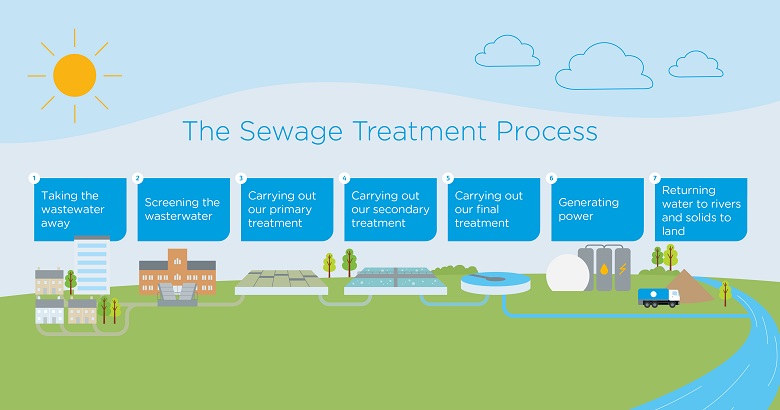

8 Stages of the Wastewater Refine Phase One Bar Testing Elimination of big products from the influent to prevent damages to the facility's pumps, valves and various other equipment. The procedure of dealing with and also redeeming water from wastewater (any type of water that has actually been used in homes, such as flushing bathrooms, washing dishes, or showering, and some water from industrial usage and also tornado drains) begins with the expectation that after it is treated it will certainly be clean enough to reenter the environment.

Fascination About Uv Filtration

According to the EPA, The Tidy Water Act (CWA) establishes the basic structure for managing discharges of toxins right into the waters of the USA and managing high quality criteria for surface area waters. Under the CWA, EPA sets wastewater requirements for market. The EPA has actually likewise developed national water top quality standards suggestions for pollutants in surface area waters.

Associated White Papers Select Products Phase Two Testing Removal of grit by flowing the influent over/through a grit chamber. Great grit that finds its means right into the influent needs to be gotten rid of to avoid the damages of pumps as well as equipment downstream (or influence water circulation). As well little to be screened out, this grit requires to be removed from the grit chamber.

Phase 4 Oygenation Air is pumped into the aeration tank/basin to motivate conversion of NH3 to NO3 and also supply oxygen for germs to remain to propagate as well as expand. As soon as converted to NO3, the germs remove/strip oxygen molecules from the nitrate particles and also the nitrogen (N) is provided off as N2 (nitrogen gas) - uv filtration.

This starts in the aeration tank. The primary function of the aeration tank is to pump oxygen into the tank to urge the failure of any type of organic product (and the growth of the microorganisms), along with make certain there is adequate time for the natural product to be damaged down.

7 Simple Techniques For Uv Filtration

This procedure is managed to provide the most effective problems for bacterial development. Oxygen gas [O2] degrees below 2 ppm will certainly kill off the germs, decreasing efficiency of the plant. Liquified oxygen tracking at this stage of the plant is important. Ammonia as well as nitrate measurements are usual to measure just how reliable the microorganisms remain in transforming NH3 to N2.

Phase Five Additional Clarifier Dealt with wastewater is pumped right into a secondary clarifier to allow any kind of staying organic debris to clear up out of treated water circulation. As the influent leaves the aeration procedure, it flows right into a secondary Read More Here clarifier where, like the main clarifier, any really small solids (or penalties) sink to the base of the container.

With the enhanced concentration of bacteria as component of the aeration stage, there is go to website a demand to examine the outbound effluent for germs visibility or lack as well as to decontaminate the water. This makes certain that more than specified concentrations of bacteria are not launched right into the atmosphere. Chlorination is the most common as well as cost-effective sort of sanitation however ozone and UV sanitation are likewise boosting in popularity.

The Ultimate Guide To Uv Filtration

Water is directed from the Head Tank to the Claricone clarifier. Water gets in the clarifier at the blending zone situated in the bottom of the Claricone - uv filtration. Lime is included in the water in this area where it reacts with the calcium as well as the magnesium in the water to form speeds up.

After enough time, fragments comply with each other as well as turn into larger particles, or, floc, which is prone to work out in water. This procedure of floc development is called flocculation. To aid in the flocculation of fragments, an anionic polymer is included in the mixing area of the web link cone. Explanation of water is accomplished by the seperation of suspended solids from water by gravity.

The made clear water steps up slowly, eventually overlooking the effluent weir to the cone electrical outlet and on the to filters for more treatment. The water plant incorporates a solitary phase lime softening operation to remove solidity. Solidity is caused by the existence of liquified bivalent and also polyvalent steel ions, mostly calcium and also magnesium.

This is included both in the clearwell and also the high service discharge as water gets in the distribution system. Hydrofluosilicic acid offers the source of fluoride, which is beneficial in the avoidance of dental caries in youngsters. A fluoride focus of 1. 1-1. 2 mg/l is normally preferable in the plant faucet.